PLASTIC

- HOME

- BUSINESS

- PLASTIC

In the Plastics & Metal Mold Business, we mainly manufacture, assemble and deliver plastic molded parts for automobiles. They range from large to small parts, including such interior parts as door trims and quarter trims, and such exterior components as front bumpers and fenders. Those interior and exterior parts play important roles that affect the quality of automobiles, so reliable quality and delivery are requisites. For that reason, in the Vuteq Group, the headquarters' technical center cooperates with the U.S. technical center from the production preparation stage of parts manufacturing, and as a result, we are highly regarded by our customers for efficient construction of the entire production processes, including part mold design, preparation of production equipment and ancillary equipment, and installation of inspection jigs that guarantee high quality products. With our domestic production know-how also applied to overseas production bases, the Plastics & Metal Mold Business has grown up to be a main business overseas.

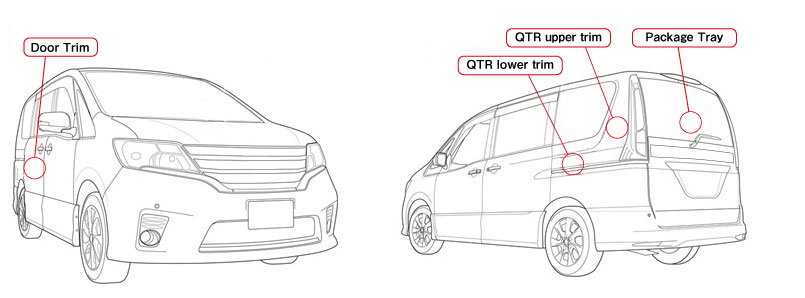

Interior parts

- Package Tray

- QTR lower trim

- QTR upper trim

- Door Trim

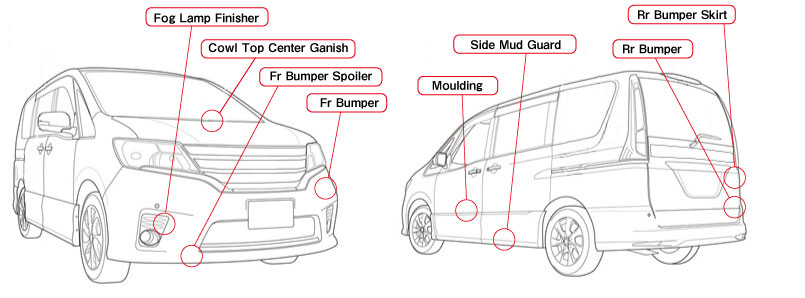

Exterior parts

- Door Moulding

- Fog Lamp Finisher

- Fr Bumper Spoiler

- Cowl Top Center Garnish

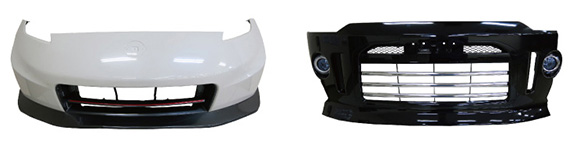

- Fr Bumper

- Rr Skirt

- Rr Bumper Spoiler

- Side Mud Guard

- Rr Bumper

Manufacture of interior parts by injection molding machine

Large-sized injection molding machine

Production by automation robot

The introduction of automation robots has increased productivity and reduced the required man-hours.

Door trim processing process

Robots have been introduced into the parts assembling operations. By automating the assembly process, we have increased productivity, reduced errors and improved product quality.

Bumper / pillar processing process

Assembly process

Shipping process

- The manufactured parts are orderly arranged and delivered to car manufacturers just in time.