TECHNICAL DEVELOPMENT

- HOME

- BUSINESS

- TECHNICAL DEVELOPMENT

The manufacturing technology of the Vuteq Group is supported by Technical Center, which has three major roles: "start-up support for new production", "advanced technology development" and "technical support". The “start-up support for new production" involves an important task, that is, preparation of all production processes before starting production of new products at domestic and overseas factories by installing necessary production equipment and designing efficient plant floor layout for increasing productivity and reducing cost. The “advanced technology development” mainly involves the development of recycled materials for automobile parts, with the strength, heat insulation performance, and weight reduction, as well as environmental friendliness taken into account. The “technical support” includes various tasks intended to improve productivity at factories in Japan and abroad.

In addition, the Technical Center provides engineer and designer trainings in cooperation with overseas technical support centers in order to improve the group's overall technical skills and product quality. In the case of production of new parts, it participates in the design stage for developing a product that is most suitable for the specifications requested by the customer, and conducts various tests and data analysis on prototypes, and makes a proposal on the overall production processes up to quality evaluation. Thus, the trust of the Vuteq brand has been established.

Prototype molding machine

High quality products are produced with the leading-edge technology.

- 3D printer to manufacture resin prototypes

- Environmental testing machine to test the durability of temperature change

- Durability test

- CAD room to design various parts

- Data analysis of various tests

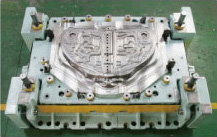

Mold manufacture

The metal mold is an important element that governs the appearance, quality, performance, and productivity of the product, so the Vuteq Group is also placing emphasis on die making.

Main product

- Sheet metal press die

- For forming, punching and bending steel plates

- Injection molding die

- For forming plastic molds

- MAW mold

- For insert-molding glass

- Floss mold

- For simultaneously molding resin and fabric

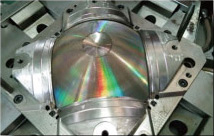

- Condenser lens mold

- For forming acrylic resin mold

- CFRP mold cutting die

- For forming and cutting CFRP mold in the same process

The Vuteq Group effectively utilizes the following

“three types of technologies”

to produce high-precision dies.